Lamination

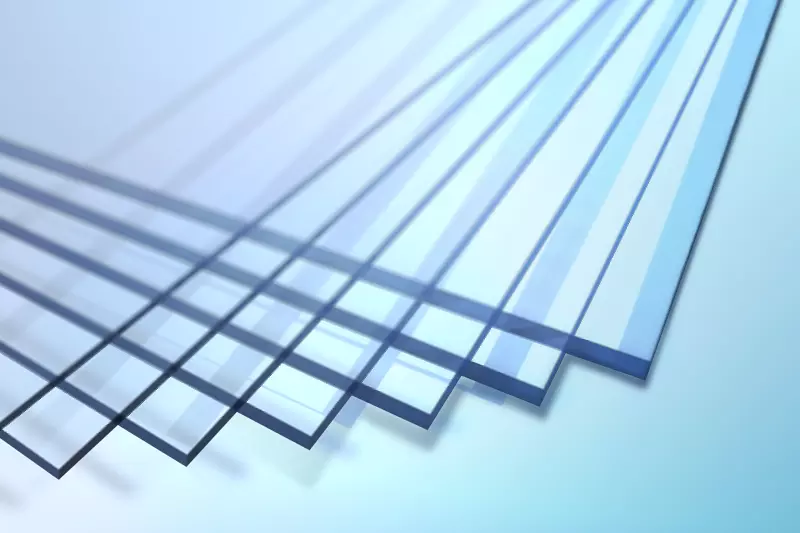

Plastic lamination is the process of bonding two or more layers of material to form a high-performance composite sheet. This improves essential properties such as impact resistance, stability and sound insulation.

The KASIGLAS® know-how not only enables the implementation of individual customer requirements, but also drives the development of state-of-the-art technologies and continuously expands the product depth.

The multi-layer composite construction offers additional equipment options, including:

- Dimmable windows

- Smart Heating Systems

- Invisible Defrost System

- Transparent displays

Quality promise:

- All “Made in Germany”

- All work steps from a single source including highly professional final inspection

- Ensuring high optical quality

- Own paint development and production process technologies

- Development of individually requested customer solutions

- Prototype construction

- Extensively certified workflows, including DIN EN ISO 9001:2015.